they range from a small 40 amp air plasma system, barely the size of a two-slice toaster but boasting the power to cut through ½ in thick steel, up to an 800 amp system that can slice through 6-1/4 in stainless with ease. This gets even tougher when considering the wide variety of plasma cutters designed to be the cutting tool that rides on the CNC machine.In the Market for a CNC Plasma Cutting Machine? | Fabricating.Connect the power cord of the plasma power to the power supply of the workshop (three-phase 380V, 50HZ) according to the power. Fix the plasma cutter with 6 anchor bolts and adjust the equipment with the balance level. Remove the wire on the left side and place it parallel to the plasma cutting machine.

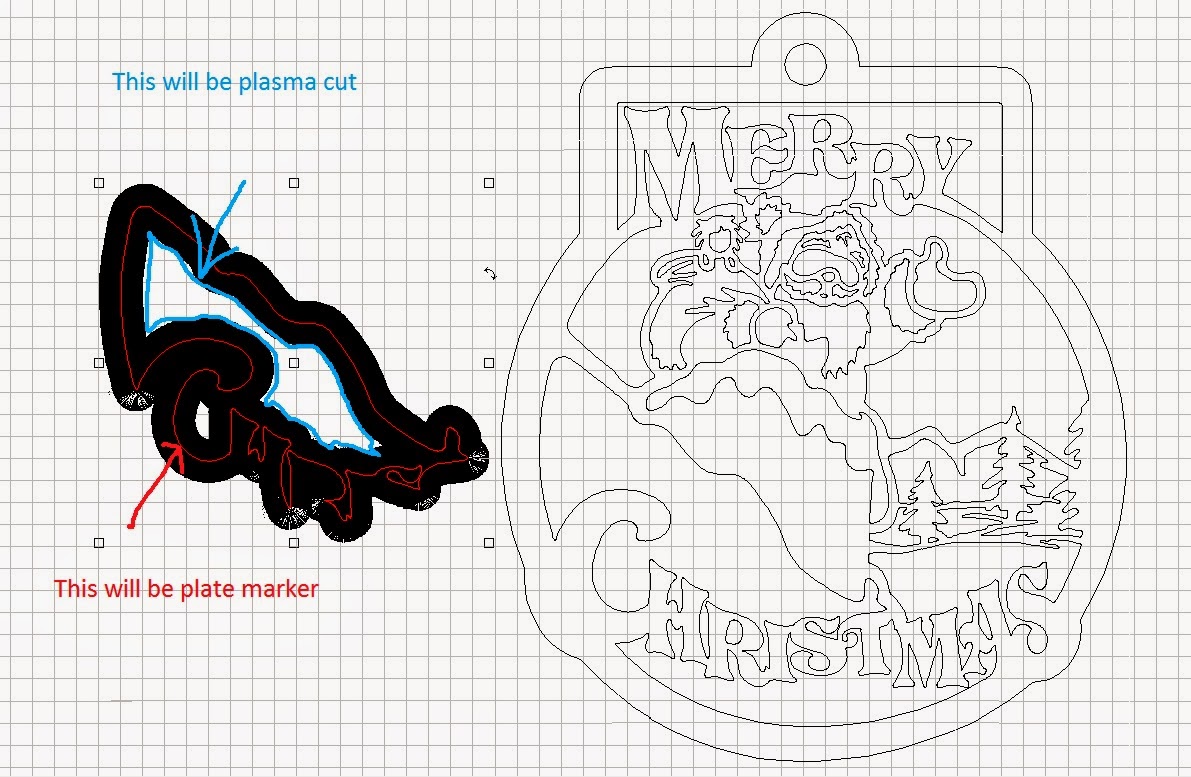

#OFFSETS IN SHEETCAM PLATE MARKER MANUAL#

On many CNC machines, the production interface is built into controller that is part of the machine.

#OFFSETS IN SHEETCAM PLATE MARKER CODE#

This is the program used to drive the torch manually, set the tool origin or offset and run the machine code to product the part. That is supplied with the CNC plasma cutter is used to control the machine.

Which is the best application for plasma cutting?.Plasma cutters operate by forcing a gas or compressed air at high speeds through a nozzle. What is CNC Plasma Cutting Machine? CNC plasma cutting refers to the cutting of metals using a plasma torch controlled from a computer. What is the CNC plasma cutter machine? - Quora.

0 kommentar(er)

0 kommentar(er)